Quantum Computing (3/3)

It’s the moment you’ve been waiting for! Part 3 of 3 of our quantum computing chat! if this is your first time tuning in, I’d like to first say welcome and second encourage you to back track to the last two blogs. If you’ve been following along, welcome back and let’s dive in!

*recap*: Qubits can hold a superposition, aka they can be “0” and “1” at the same time. However, they aren’t in a superposition all the time, and are actually quite tricky to put in and keep in a superposition. They require a milliKelvin environment, which is created inside a cryostat. Creating and maintaining a milliKelvin temperature takes a lot of energy, so cryostats must be kept small in order to limit the energy consumed. Additionally, they need to be isolated from heat, so any lines coming into the sections must be extremely cold. This brings us to XMA’s two goals when designing and manufacturing cryogenic RF components: superb thermal grounding and increased density.

Let’s begin this discussion by chatting about attenuators (our most popular cryogenic product line). And you may be asking my first question when starting my job here at XMA- what on earth is an attenuator? An attenuator goes in to an RF line to “attenuate,” or lessen, the power of the signal going through the line while maintaining the signal integrity. Mechanically, it is a small resistive chip, which we make in house from a substrate base and sputtered metals, that we put inside a metal tube with some teflon to ensure we meet all the right specs. The attenuator will snap or screw onto a wire, plate, or other connector, and the signal will travel through it. So if it’s that straightforward, who cares if it’s cold? Quantum scientists (and us).

We’ll start with the heat issue, since it’s a bit more nuanced than density. Heat seeks an equilibrium state, meaning that heat seeks to warm the cold around it. I like to think of it as a liquid in a bucket with a divider: The liquid stays in half of the bucket when the divider is in, but as soon as the divider is removed, it spills into the other half. Heat wants to do the same thing. It wants to make everything the same temperature. Thus, we have quite a problem when attenuators create heat in super cold environments. The heat has a field day, trying to warm up its environment. Luckily for us, heat is ~lazy~. What do I mean by this? Heat likes the path of least resistance. It doesn’t like going over the hill and through the woods to get to where it’s going, it wants to get there ASAP. Unfortunately, the path of least resistance for heat produced by attenuation is to continue down the RF line, contaminating the cold vacuum areas below it. This makes our job as engineers and manufacturers to decrease the resistance in the path from the chip, to the wall of the attenuator, through the attenuator body, and into the cold plate. If we can choose the right materials and design to make this an easy path, the heat will go there, no questions asked. However, making this path easier than continuing down the line is a huge challenge. Luckily XMA has some brilliant minds. Working with scientific partners, we are constantly designing new products to distribute heat into the plates and out of the RF lines. Stay tuned for our next product launch ?

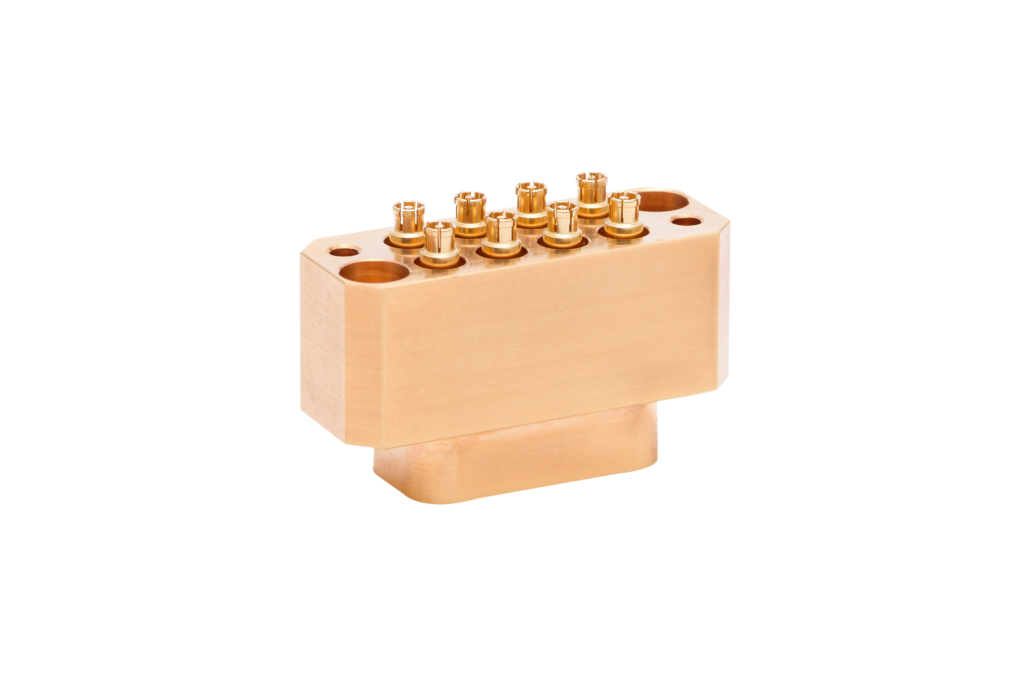

Other than dispersing heat through the plates, quantum engineers are battling scale-up issues. More qubits lead to more RF lines, but as mentioned, producing larger fridges has many challenges. Therefore, we are focusing on increasing the density of our products. We began by designing the bulkhead attenuator, which eliminates a connection point at each port and requires less space in the fridge. Following that, we released cryogenic SMP and SMPM attenuators, which boast smaller connection radii. However, they fall flat when it comes to installation due to their size. To solve these issues, we manufactured a series of cryogenic block attenuators with multiple ports. Using these, scientists populating the fridges are able to install 8, 16, or even 24 ports at one time. This increases density and decreases installation time, making them a great solution for crowded fridges. Following our initial design, our team is constantly working to improve and compact our high density blocks.

Ultimately, XMA’s goal is to combine these two efforts to make super dense, extremely well thermally anchored attenuator products. Each day we spend in the lab is one step closer to overcoming these challenges and furthering quantum computing. We can’t wait to show you what’s next! As always, if you have any questions, don’t hesitate to reach out to us at quantum@xmacorp.com. Happy reading!